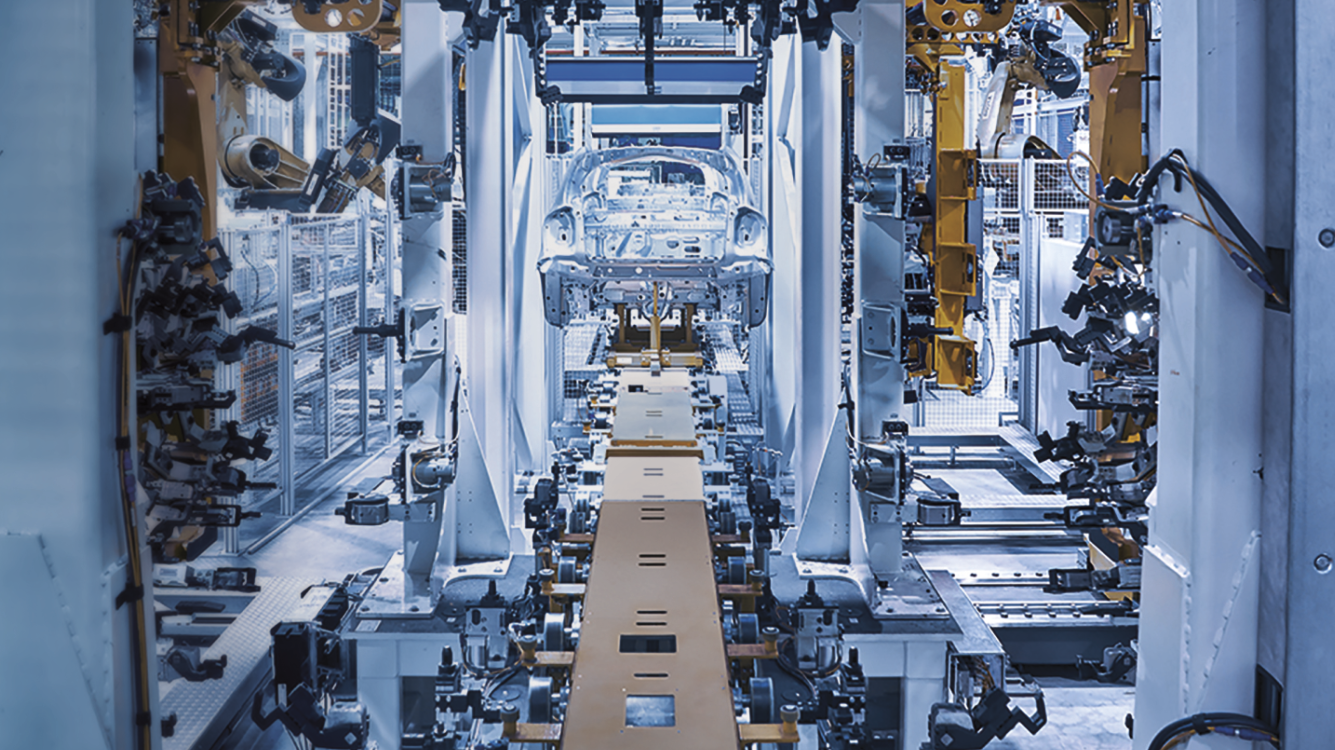

Axle assembly & logistics

At thyssenkrupp we perform axle assembly and logistics services for our customers in the automobile industry. Chassis modules and complete axle systems are produced just-in-time and delivered just-in-sequence according to customers' needs. Our services include module and system assembly and if required quality and supplier management for our customers.

/thyssenkrupp_logo_claim_d.svg)

-thyssenkrupp_3d-druck_image_w328_h140.jpg)